The automotive sector is one of the top-selling industrial sectors worldwide. The transport of equipment, individual or spare parts plays a significant role in this success.

WETROPA-GROUP is your partner for efficient and sustainable packaging logistics. Whether packaging for painted, chrome-plated or scratch-sensitive components, inserts for small load carriers, large load carriers, special load carriers such as trays, CKD packaging or packaging for charging stations & batteries. Our know-how is based on 50 years of experience in the industry. We promise: short project durations, tailor-made solutions and sustainability.

A sustainable packaging solution with Wetropa

Our sustainable packaging solutions for the automotive industry and its suppliers meet the highest demands for internal logistics, both for external truck transport and overseas transport. We develop packaging concepts for the shipment of components and assemblies, e.g. as SLC, LLC, SLC or CKD (Completely Knocked Down) packaging. We offer you individual solutions or standardized concepts, tailored to your requirements.

Through our certification according to IATF 16949:2016 we understand and live the requirements of the automotive industry and its suppliers.

Advantages of load carriers in the automotive industry

Returnable packaging is sustainable

Development

The creative minds at WETROPA soon realized: with the 3rd dimension we can achieve more!

After a short time, the first prototypes followed and after some fine tuning it was ready –

THE NEW LOAD CARRIER FOR THE AUTOMOTIVE INDUSTRY!

An inlay is clipped into the customer-specific load carrier. This snaps firmly into place, is thus protected against loss and can still be easily replaced. The bottom of the inlay consists of a hollow chamber plate. On top of this are moulded parts made of PE foam, which serve to hold the components. And this is where the additional dimension comes into play: these are manufactured in 2½-D to 3D and precisely reproduce the contours of the lying components! Nothing gets out of line here!

Perfect solution: horizontal transport of the gaskets, the retainers are visible and nobody can get lost, they do not bump against each other, easier removal at the production line.

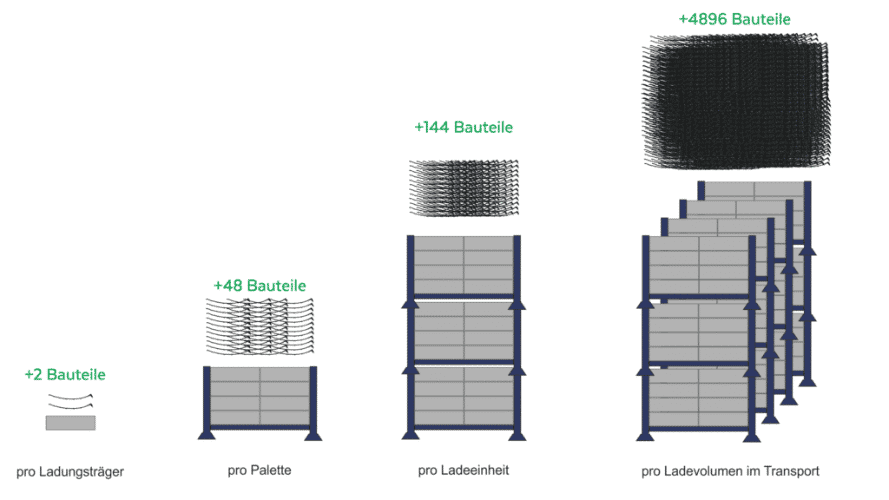

higher component volume on the belt

- Seal with retainer in upright position

- Retainer stored at the bottom

- Slight loss of inlays and components

- Joining of the brackets

- Damage to the seals

- Unwieldy placement and removal of components

- Voluminous charge carriers with a small number of seals

- 7 seals per load carrier

- 6 load carriers per pallet

- 18 load carriers per load unit

- Existing load carriers (customer-specific, internal reusable system) are to be equipped with inlays

- If possible, the seals should be positioned horizontally and the retainers visible

- Inlays and components must not be lost

- Components must not touch each other

- Improved removal of the seals

- Improved storage and transport

- Higher packing density in the load carrier

- Higher packing density on stanchion pallet

- Higher packing density per load unit

Optimizing packaging logistics with special load carriers

Special load carriers are a customized loading device with which packaged goods can be transported efficiently, safely and in accordance with all requirements. In the automotive industry, special load carriers are used when standardized solutions reach their limits.

Thanks to their robust and safe design, special load carriers in the automotive industry prevent damage and accidents at work. At the same time, the optimized packing density of a special load carrier can also save freight costs.

Last but not least, special load carriers fit perfectly into the storage and transport processes in the automotive industry. In the assembly area, too, the required components can be removed exactly in the specified assembly sequence thanks to suitable special load carriers.

Compartments – the ideal complement for special load carriers in the automotive industry

Compartments are particularly popular as a packaging solution in the automotive industry. After all, they efficiently separate goods from one another thanks to integrated separating inserts. In this way, it is possible to store and transport small parts as well as elongated and large-area components in a shock-resistant manner.

Compartments for automotive components are designed as individual solutions, which means they can be optimally tailored to existing containers as well as special load carriers for the automotive industry. Simple loading during the packaging process and effortless removal after transport are also arguments in favor of using compartments.

Tooth strips made of foam are ideally suited for holding components from the automotive industry with a precise fit and fixing them securely. In this way, a precisely fitting assembly can be realized, which preventively counteracts slipping, collision and scratching of the packaged components.

With the appropriate toothed strips, your packaged goods are optimally protected when they are transported on a special load carrier, for example. These have special fixtures in load carriers which allow toothed strips to be accommodated. In addition, toothed strips can also be designed as inserts for plastic containers.

Special load carriers for the automotive industry – Get advice now from Wetropa

The Wetropa Group is your professional partner for the development and production of special load carriers for the automotive industry and its suppliers. We focus not only on the load carriers themselves, but also on suitable supplementary products such as compartments and toothed strips, which together form a packaging solution.

Products

FAQ

1

What is a special load carrier?

2

What is the best packaging for the automotive industry?

Special load carriers are particularly popular in the automotive industry and its supplier industry, after all they can be optimally tailored to the products to be transported. These special load carriers are supplemented by packaging solutions such as compartments and toothed strips.

We make your packaging solutions more innovative and sustainable with ReFoam and RePaper