ARPLANK 100% recyclable – high-qualitiy and sustainable packaging

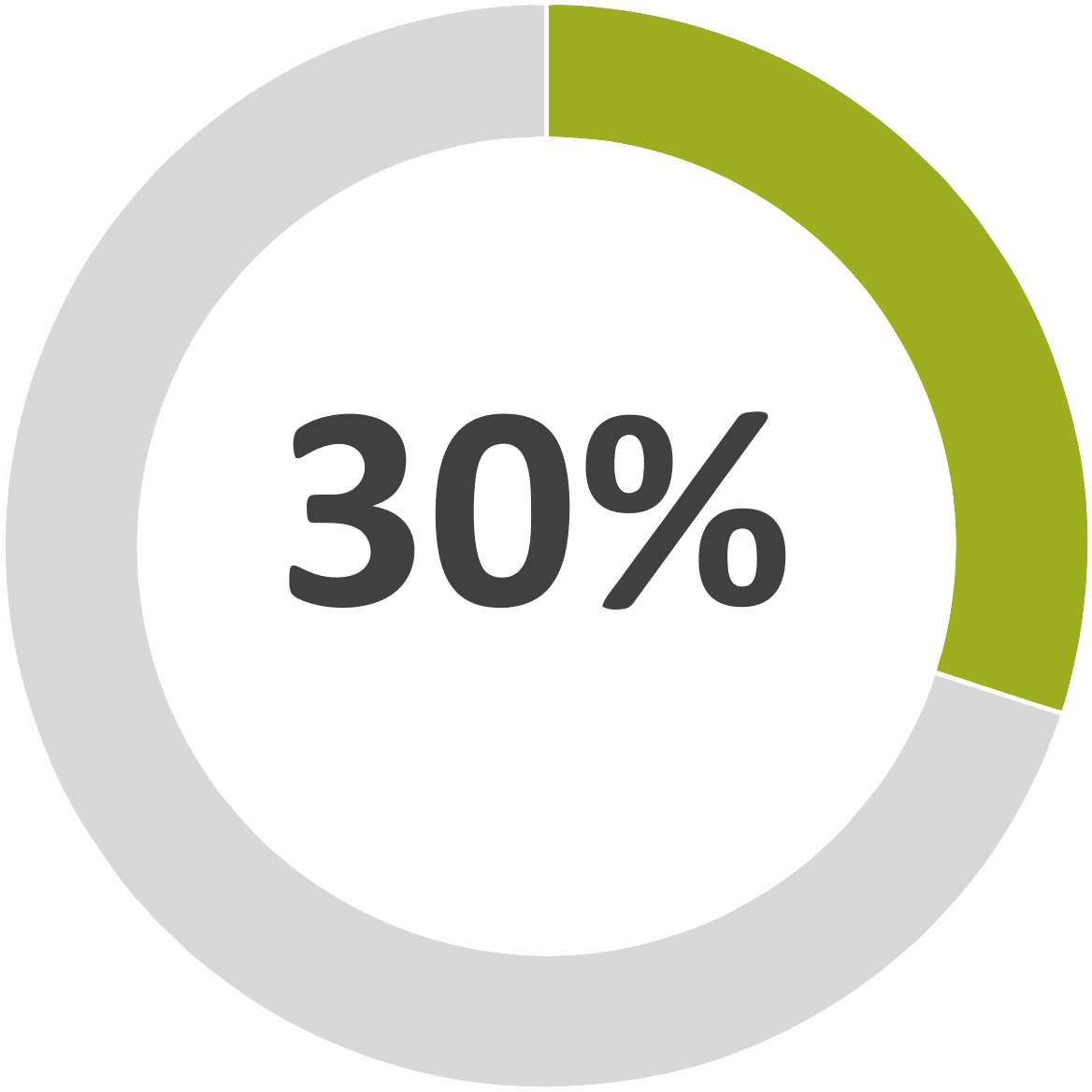

Recycled material

ARPLANK is made from at least 30% recycled material.

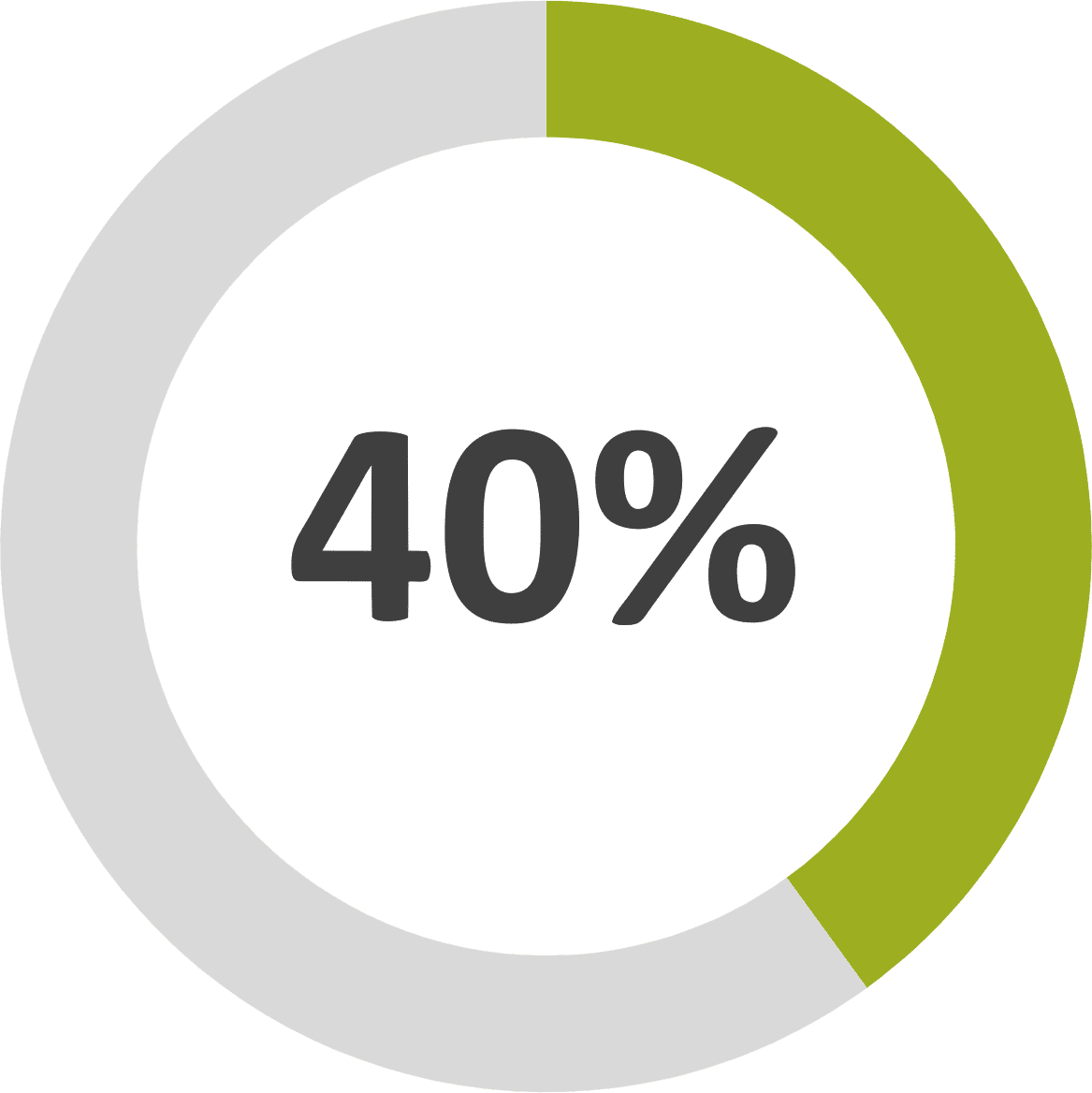

Material savings

With the same cushioning properties, ARPLANK can save 40% material per package.

Reshaping

Almost 100% recovery even after multiple impacts.

Recyclable

ARPLANK is 100% recyclable.

ⓘ

What is ARPLANK?

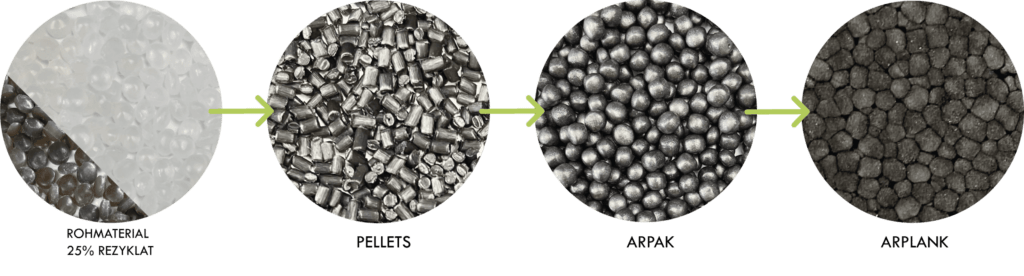

ARPLANK is a highly elastic, closed-cell foam made of expanded polyethylene (EPE).

During the fusion process, the outer shells of the polyethylene are thermally bonded together, creating a three-dimensional sphere that absorbs and dissipates energy equally, even in three dimensions.

There is no outgassing of chemical substances in ARPLANK. ARPLANK is isotropic and is therefore perfect for the production of high quality and protective foam packaging.

Comparison of materials

Thanks to its first-class quality, the material is particularly durable, just like all other ReFOAM products, and can therefore also be used as reusable and multifunctional packaging. The aspect that material can be effectively saved by using the high-performance ARPLANK also benefits the ecological balance of the material. Last but not least, ozone-depleting compounds such as CFCs and HCFCs are not contained in the versatile packaging material.

Scratch-sensitive surfaces, such as those with a high-gloss finish or chrome effect, can also be realized with the block material.

Convincing material properties for high-quality EPE packaging

As an energy absorbing packaging material for products requiring shock absorption, vibration damping, insulation and chemical resistance, ARPLANK is ideal. It can withstand multiple impacts without damage and is abrasion resistant. In addition, ARPLANK is very lightweight and multi-directional.

Conventional foams have different properties along the extrusion, vertical and horizontal axes. ARPLANK’s cushioning properties are the same regardless of orientation, making it an ideal and versatile product for protective packaging applications.

Thanks to its excellent material properties, ARPLANK is ideally suited for packaging solutions of all kinds. At the same time, the special material property enables a lower weight and reduced volume of a packaging solution.

In addition, it is known for its excellent isothermal properties; after all, the material proves resistant to extreme temperatures from -60 to -100 °C. Last but not least, the material is free of chemicals as well as volatile organic compounds.

ARPLANK is made from 25% to 50% recycled material and in turn can be 100% recycled.

ARPLANK provides excellent shock absorption and repeated impact resistance.

Its optimal density makes ARPLANK a volume-reduced, lighter and safer packaging option.

Very good isothermal properties. ARPLANK is stable from – 60 to 100 C.

ARPLANK is chemically inert; free of chemicals and volatile organic compounds (VOC).

ARPLANK is an isotropic block material – equal energy absorption across all three dimensions.

Advantages of ARPLANK – achieve more with less material

- More design options – better protection

- Optimum physical properties

- Very well suited for scratch-sensitive surfaces (e.g. high-gloss painted or chrome-plated surfaces)

- No abrasion

- Less concavity in die-cut products

- Correspondingly high material blocks, therefore less lamination required

- Weight savings in manufactured parts

Environmental advantages of ARPLANK

ARPLANK is one of the few EPE products (made from expanded ARPAK) that is manufactured without VOC blowing agents.All ARPLANK products are fully recyclable and recyclable. It is designated as recycling category 4 by the SPI (Society of the Plastics Industry) recycling standard.

All ARPLANK products are free from CFC, HCFC and other ozone depleting compounds. All ARPLANK products are free from any restricted heavy metals, such as lead (Pb) or lead compounds, mercury (Hg) or mercury compounds, and chromuim VI (Cr-VI) or chromium compounds, and also contain no halogen compounds or brominated (Br) compounds.

ARPLANK is not only convincing all along the line from the point of view of sustainability; the material also has a particularly gentle material composition. As one of only a few products made from expanded Arpak, the material is manufactured without the use of polluting VOC blowing agents. Free of restricted heavy metals of all kinds as well as halogen compounds and brominated compounds, ARPLANK products from Wetropa score points for their unproblematic composition.

Request an individual packaging solution

If you are interested in detailed information about ARPLANK or our ReFOAM initiative, our team of experts is always at your disposal.

We look forward to your inquiry about our sustainable product range.

Possible applications

- Automotive frame

- Inserts

- Container linings

- Electronics packaging

- Container and ATA case inserts

- Seals

- Paintings/galleries/art market

- Military applications

- Reusable load carriers

- Seat pads

- Tooling inserts

- Packaging for consumer goods

- Partition walls for glass

- Impact absorption

- Landing and drop mats

- Temperature regulating containers

- Wall insulation

- Kayak floats & roof blocks

- Buoys and floating fenders

Product modularity

- Color: Black

- Block size: 1800 x 1200 x 150 mm

- densities: 20 / 30 / 45 (Kg/m3)

- Low lamination effort due to optimal geometry of the material blocks

- Easy cutting with all common processing methods

- Reverts to its original shape almost 100% after an impact

- Clean cuts due to minimal concavity of the material

ARPLANK – the innovative and sustainable packaging material

The innovative packaging material ARPLANK combines unique performance with an excellent environmental balance. While the material properties ensure optimum safety of the packaging contents, the raw materials are part of a circular system that conserves resources and the climate in equal measure.

The closed-cell and highly elastic expanded polyethylene foam is part of the sustainable ReFOAM product range, which offers material solutions with a low ecological footprint at fair conditions.

First-class performance meets special ecology

ARPLANK is not only fully recyclable, but is also made from 25% recycled raw materials. But even apart from its environmental compatibility, the foam is characterized by special material properties that make it an excellent choice for high-quality and protective packaging solutions. For example, ARPLANK dissipates energy equally in all directions thanks to its three-dimensional spherical structure, which is created as a result of the thermal fusion process.

This creates a secure cushioning that absorbs even strong physical loads and almost completely deforms back to its original shape even after multiple impacts. Last but not least, the closed-cell and isotropic material does not outgas any chemical substances.

Easy processing and universal applications

ARPLANK is known as a universally applicable material for high-quality and safe foam packaging made of expanded polyethylene. The extra-high material blocks can usually be processed into shapes to meet specific requirements without lamination. Compatible with all common processing methods, the block material can easily be cleanly contour cut, water jet cut, punched, milled, welded and laminated, for example.

From the automotive industry to the packaging of sensitive products, ARPLANK can be used in a wide variety of contexts, because not only outer packaging, but also inserts, container linings and suitcase inserts can be made from the sustainable foam. For example, wall and impact insulation, seat pads, and landing and drop mats can be made from the flexible material. Packaging for electronic products and sensitive art objects can also be realized with the material from the ReFOAM portfolio.

Ecological and gentle – with ARPLANK to a sustainable production culture.

ARPLANK not only offers the perfect conditions for producing high-quality EPE foam packaging for a wide range of applications, but also impresses with its first-class environmental performance. As a high-quality monomaterial consisting of 25% recycled raw materials, the sustainable foam can be completely recycled by type and then returned to the material cycle. This applies to all innovations from the ReFOAM product family, which is based on a special closed-loop recycling system. The Society of the Plastics Industry’s rating of ARPLANK in recycling category 4 confirms our efforts for recyclable high-performance materials for the packaging industry.

Thanks to its first-class quality, the material is particularly durable, just like all other ReFOAM products, and can therefore also be used as reusable and multifunctional packaging. The aspect that material can be effectively saved by using the high-performance ARPLANK also benefits the ecological balance of the material. Last but not least, ozone-depleting compounds such as CFCs and HCFCs are not contained in the versatile packaging material.

We make your packaging solutions more innovative and sustainable with ReFoam and RePaper