ReFoam and RePaper

– our sustainable packaging solutions

As a company with an innovative and forward-looking focus, Wetropa always acts with sustainability in mind. For example, we have been climate-linked since 2019 and invest around 5% of our turnover in sustainable development, with material-oriented solutions such as ReFoam and RePaper playing a key role.

The idea behind ReFoam

Setting new standards is our goal. We have implemented our requirement to develop a sustainable product range with ReFoam.

Wetropa’s ReFoam products are made from sustainable foams, which are mono-materials that are unmixed and fully recyclable in a closed loop. Some recycled materials are used in the production of the materials. As a medium-sized company, we are committed to offering the greatest possible transparency, acting responsibly and building long-term partnerships that are characterized by quality and service.

100% recyclable foam

Our ReFoam packaging is made from sustainable foams that are mono-materials, single-origin and fully recyclable.

Durable

Our ReFoam packaging is durable and can be reused.

Conserving resources by saving CO2

By continuously improving processes and optimizing the use of materials, we already take resource-saving use into account when developing our foam packaging.

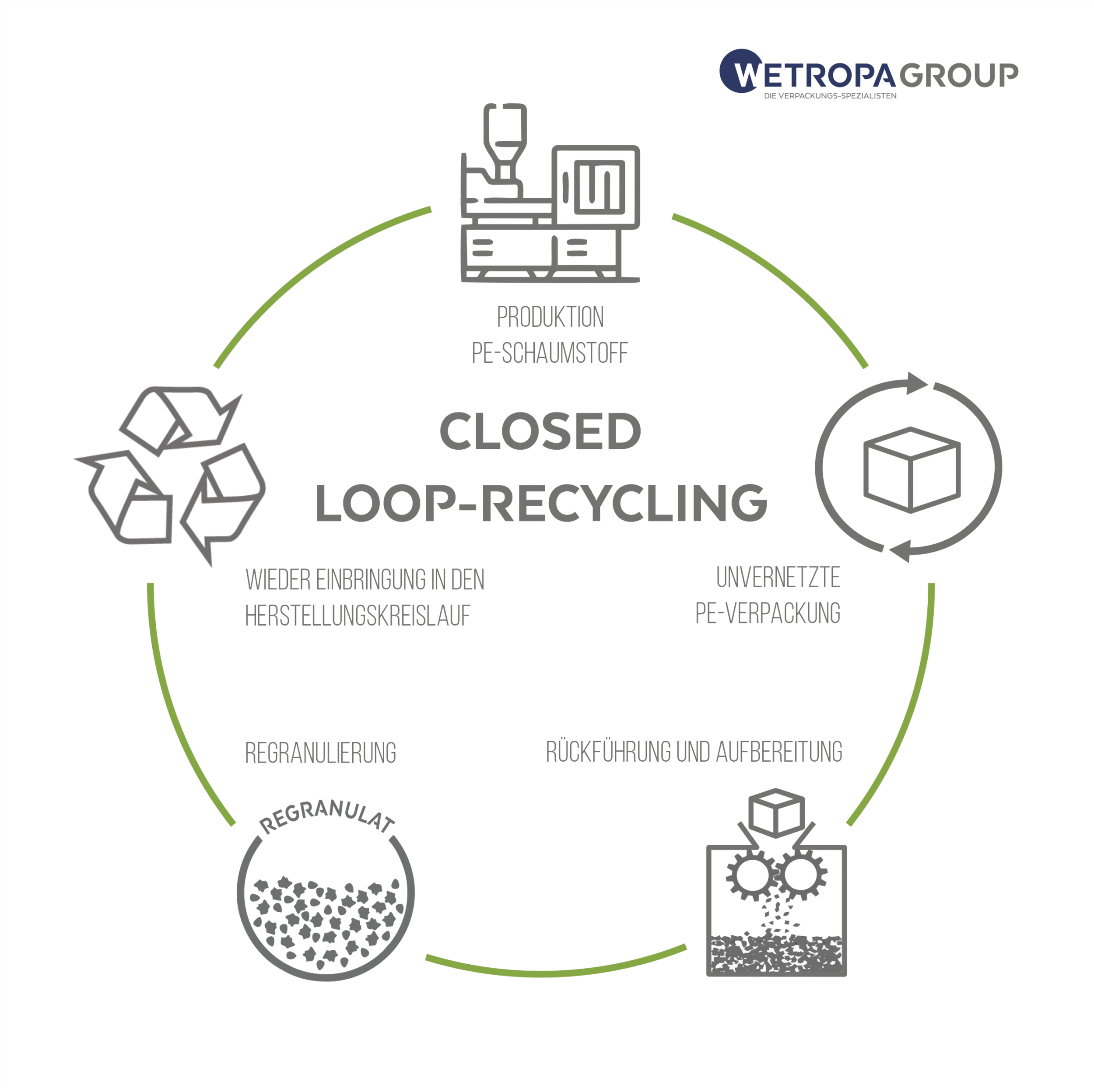

Circular economy through foam recycling

Packaging waste is first roughly shredded in our in-house plant and pressed into bales before being pressed into regranulate in a special plant. This regranulate can be 100% reintroduced into the production cycle for PE foam.

The materials from the Wetropa Group’s ReFoam product range cover numerous material properties and applications. As many of our packaging materials are fully recyclable and contain a recycled content, there is a large selection of sustainable foams for packaging solutions.

With the ReFoam materials, the Wetropa Group is setting standards in the field of sustainable foam packaging. If you are interested in the versatile, highly functional and sustainable materials ARPLANK, Stratocell, Ethafoam, Synergy, Synergy Prime and Whisper, please contact our team of experts. We look forward to your inquiry.

From Arplank to Whisper – ReFoam materials at a glance

The Wetropa Group’s ReFoam series includes various sustainable foams for a wide range of applications. All materials are characterized by the combination of outstanding functional material properties and sustainability according to the principles of Reduce, Reuse and Recycle.

1

Arplank

ARPLANK is a closed-cell foam made of expanded polyethylene (EPE), which is characterized by excellent shock absorption and high elasticity with full recovery. The fusion process of the outer shells of the polyethylene leads to the formation of an isotropic structure that dissipates energy in all three directions.

The foam is 100% recyclable and is made from at least 30% recycled material. In constructive packaging, ARPLANK can save 40% material per package without compromising the cushioning performance. Last but not least, the material is chemically inert and free from chemicals and volatile organic compounds (VOCs).

ARPLANK can be used in a wide variety of contexts. The versatile foam is used particularly frequently in load carriers, reusable packaging, die-cut inserts, constructive packaging, cases and KLT inserts.

- Color: black

- Volume weight: 20, 30, 45

- Suitable for: Load carriers, reusable packaging, die-cut inserts, constructive packaging, cases and KLT inserts

- Block dimensions (mm): 1.800 x 1.200 x 150

2

Stratocell

Stratocell is an environmentally friendly packaging material made from closed-cell polyethylene foam. Just like the other foams in our range, the material contains no CFCs or other greenhouse gases that could damage the ozone layer.

The pure PE material is not only 100% recyclable, which means that it can be returned to the material cycle, thus conserving resources. Stratocell packaging is also durable and can be reused.

Due to its high density and stability, Stratocell offers excellent shock absorption and excellent recovery after compression. These properties make Stratocell an ideal choice for shipping and transporting delicate and high-value products.

- Color: black, white, pink

- Volume weight: 16, 24, 30, 65

- Suitable for: Constructive packaging, punched parts

- Block dimensions (mm): 2.000 x 1.200 x diverse

3

Ethafoam

Ethafoam is a robust and lightweight packaging material made of polyethylene foam, which is mainly used in the form of constructive packaging or die-cut parts for transporting sensitive goods such as electronics, medical technology and art objects. The material is characterized by high impact resistance and formability.

In addition, Ethafoam is fully recyclable and, like all ReFOAM materials, can be reused to make new foam products or other polyethylene products Furthermore, Ethafoam does not release any harmful substances during use or recycling.

- Color: black, white, pink

- Volume weight: 18, 25, 35, 60, 105, 140

- Suitable for: Constructive packaging, punched parts

- Block dimensions (mm): 2.750 x 1.200 x diverse

4

Synergy

Synergy is an innovative, closed-cell foam made of expanded polypropylene (EPP), which is known for its excellent shock-absorbing properties and high reusability. It is a very lightweight yet durable material with high energy recovery and cushioning capacity.

Synergy is versatile and can be used in various industries. It is particularly suitable for packaging sensitive goods such as electronic and medical devices, measuring instruments and sensor technology.

The EPP foam is 100% recyclable, has a recycled content in the end product and can be used multiple times, making it an environmentally friendly packaging option.

- Color: black, white

- Volume weight: 33, 45, 64

- Suitable for: Load carriers, case and KLT inserts

- Block dimensions (mm): 2.750 x 600 x 50

5

Synergy Prime

Synergy Prime is similar to Synergy, an expanded polypropylene foam material, but it has been specially developed for use in high-end packaging applications. It is highly resilient and offers excellent shock absorption, making it an excellent choice for protecting delicate or fragile objects.

Compared to other foams, the material has a lower density. In addition, Synergy Prime is 100% recyclable and can be recycled in a closed loop, resulting in a lower environmental impact.

- Color: black, white, blue

- Volume weight: 33, 45

- Suitable for: Load carriers, case and KLT inserts

- Block dimensions (mm): 2.750 x 1.000 x 50

6

Whisper

Whisper is a high-quality PE foam with a non-cross-linked, honeycomb structure that enables high sound absorption and is therefore used in particular as a sound insulation material.

Whisper is used in various indoor and outdoor applications to ensure optimum room acoustics and pleasant noise insulation. These include acoustic partition walls, sound insulation cladding, noise barriers, sound insulation for technical equipment and much more.

- Color: black

- Volume weight: 25

- Suitable for: Acoustic wall, Acoustic ceiling, Acoustic partition wall

- Block dimensions (mm): 2400 x 1200 x 50

Reduce – Reuse – Recycle – the sustainable process

With ReFoam, Wetropa has launched an ecological product range on the market that combines sustainability with maximum functionality. A wide range of different materials and well thought-out strategies for saving materials make it suitable for use in high-quality packaging. ReFoam is based on a closed-loop recycling system and is fully thought through from the production of the packaging through to delivery.

In addition, the product range offers great potential for reuse in the context of reusable and multifunctional packaging, which is not only sustainable, but also economical and efficient. Discover the exciting range of high-quality ReFoam packaging solutions without any effort or loss of quality.

ReFoam stands for:

- REDUCE

- REUSE

- RECYCLE

Pure recycling

ReFoam products from Wetropa are sustainable foams which, as mono-materials, are single-origin and fully recyclable. In some cases, recycled material is already used in the production of the materials.

Delivery also works, thanks in part to our locations, which are distributed throughout Germany and therefore enable us to have short supply chains of less than 1,000 km. As we at Wetropa are convinced of the functional performance and ecological impact of ReFoam foams, we only use these products as raw materials when developing new packaging solutions.

We also actively promote the development of new sustainable materials through close cooperation with our suppliers and producers. Last but not least, we offer a take-back service for ReFoam packaging so that it can be professionally recycled and returned to the material cycle as recyclate.

We advise you

By working closely with customers from industry and retail, we can also make your packaging solutions more innovative and sustainable with ReFoam and RePaper. After an initial consultation, we analyze your existing packaging solutions to identify potential savings.

The idea behind RePaper

Maximum protection with minimum weight: thanks to their unique structure, honeycomb panels are the ideal packaging material for a wide range of applications.

Whether as a pallet lid, as filling material or as part of system packaging – honeycomb panels do an outstanding job in packaging.

Lightweight and stable

Our RePaper packaging is characterized by high stability and low weight.

Environmentally friendly

Honeycomb panel packaging is environmentally friendly, fully recyclable and offers the possibility of multiple use in a variety of applications.

Easy handling

Honeycomb panels are particularly easy to handle thanks to the wide range of customization options in terms of shape and size.

Efficient

Honeycomb panel packaging is efficient in production and transportation, resulting in a cost-efficient solution. In addition, they offer high energy efficiency during production.

Our honeycomb panels made of PaperCore not only offer high stability and excellent impact absorption, but can also be customized in shape and size thanks to individual cuts. These properties make them a cost-effective, versatile and flexible solution in the packaging industry.

PaperCore is not only effective and versatile, but also particularly environmentally friendly. It is made from recyclable materials such as paper and cardboard, is energy-efficient in production and can be easily returned to the recycling loop at the end of its life.

In addition, we use water-soluble glue in the production of the honeycomb panels, which simplifies the separation of materials and makes the use of aggressive chemicals obsolete.

We make your packaging solutions more innovative and sustainable with ReFoam and RePaper