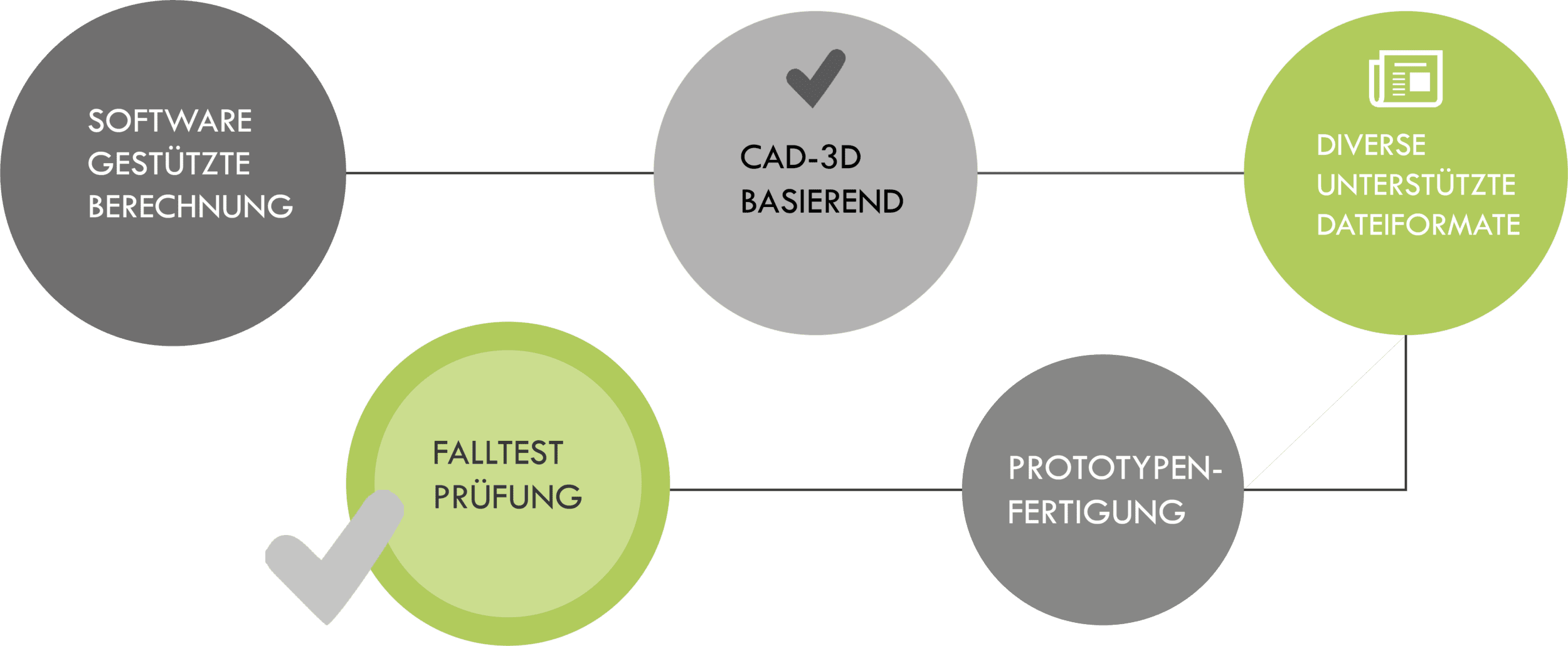

Individual goods require individual packaging that is not only functional, safe and space-saving, but also efficient and sustainable. Packaging from Wetropa is optimally tailored to the products to be packaged as part of the packaging development process, thereby meeting all customer requirements with flying colors. From needs analysis to constructive packaging development with modern CAD software to prototyping and final series production, Wetropa offers development processes from a single source.

Wetropa always develops individual packaging solutions with your needs in mind. In doing so, our experienced packaging engineers draw on many years of expertise in packaging production processes and a wide range of technical options. With the help of professional and state-of-the-art CAD software, the packaging is first precisely designed and then prototypically tested and optimized in the next step. After several test and iteration loops, we arrive at a production-ready packaging solution, which is the proud result of the packaging development.

We also respond flexibly to customer and product requirements when it comes to material selection. While our foam packaging can be made of recyclable mono-materials, system packaging offers special protection by combining different packaging materials. In the design process of system packaging, Wetropa also ensures that the different materials can be separated according to type and then returned to the recycling loop. The foams from our sustainable ReFOAM product range are characterized by their climate neutrality as well as their environmental compatibility; after all, they were developed with the three Rs Reduce, Reuse and Recycle in mind.

Request an individual packaging solution